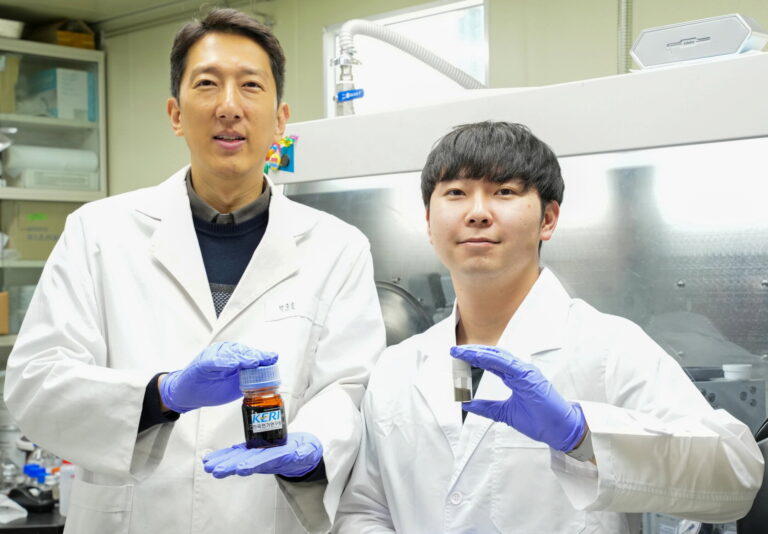

Korea Electrotechnology Research Institute (KERI), a pioneering research institute for all-solid-state (sulfide-based) batteries that are free of fire and explosion hazards, has recently developed a novel technology that could pave the way for mass production of low-cost solid electrolytes. The research is published in the journal Batteries & Supercaps.

The team led by Dr. Jun-ho Park at the KERI’s Next Generation Battery Research Center developed a “one-pot” synthesis method to produce high-purity solid electrolytes without the need to use expensive lithium sulfides and additives.

There are two methods for producing solid electrolytes: dry synthesis using high-energy ball milling, and wet synthesis using chemical reactions in solution. The team focused on wet synthesis, which has advantages in scale-up and mass production, and succeeded in producing high-purity solid electrolytes by optimizing the synthesis reaction in solvent.

The key advantage of this method is that it does not require expensive lithium sulfides (Li2S). Lithium sulfides account for up to 95% of the cost of starting materials for solid electrolyte production. In addition, lithium sulfides often remain as unreacted impurities during wet synthesis, leading to degraded cell performance. Some have proposed lithium sulfide-free synthesis methods, but these would require the addition of expensive additives and often produce residual impurities, resulting in unsatisfactory performance.

On the contrary, the one-pot synthesis method developed by KERI enables the production of high-quality solid electrolytes without lithium sulfides, additives or additional processes. Compared to the existing lithium sulfide-based process, the material cost is reduced to 1/25th and the accelerated production time would significantly contribute to the mass production of solid electrolytes.

“KERI’s years of experience in solid electrolyte production enabled us to find a fast and easy way to produce high-purity solid electrolytes through optimized chemical reaction combinations of starting materials in organic solvents,” said Dr. Park. “We are excited that this technology will help address the biggest challenges in commercializing all-solid-state batteries, namely price competitiveness and mass production issues.”

The KERI has filed a patent application for this technology and published papers in local and international journals. Anticipating that this achievement will attract strong interest from companies developing all-solid-state batteries, the institute plans to seek opportunities for technology transfer.

More information:

Youngjun Huh et al, Solution‐Processed Synthesis of Nano‐Sized Argyrodite Solid Electrolytes with Cavitation Effect for High Performance All‐Solid‐State Lithium‐Ion Batteries, Batteries & Supercaps (2023). DOI: 10.1002/batt.202300036

Provided by

National Research Council of Science & Technology

Read the full article here