A research team led by Professor Seok Ju Kang in the School of Energy and Chemical Engineering at UNIST has unveiled a technique for mass-producing polymer solid electrolytes, crucial components in batteries. Their paper is published in the journal Energy Storage Materials.

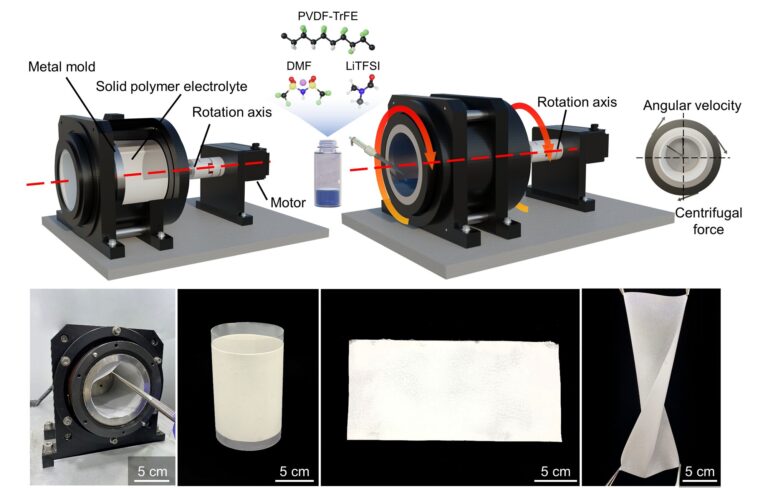

Departing from the traditional melt casting method, the team introduced a horizontal centrifugal casting method to overcome existing limitations. This innovative approach has redefined the production process for high-quality polymer solid electrolytes, revolutionizing the industry.

Drawing inspiration from the horizontal centrifugal casting technique used in producing iron pipes, the research team successfully achieved a uniform polymer solid electrolyte by rotating the solution horizontally during manufacturing. This method ensures minimal raw material wastage and offers superior electrochemical performance, economic feasibility, and effectiveness compared to conventional methods.

Professor Kang commented, “By adapting the iron pipe manufacturing process, we have developed a method capable of mass-producing uniform and high-performance solid electrolytes.”

The newly developed technology enables a remarkable 13-fold increase in production speed by eliminating the need for drying polymer solutions and vacuum heat treatment, thereby streamlining the manufacturing process significantly.

Moreover, the production volume can be easily adjusted by varying the size of the horizontal centrifugal casting cylinder, ensuring consistent thickness and surface quality of polymer solid electrolytes, ideal for battery production.

Lead author Hyunwoo Kim from the School of Energy and Chemical Engineering at UNIST stated, “Through this method, we have achieved enhanced battery stability and performance without altering the material composition.”

Professor Kim said, “The elimination of the time-consuming and energy-intensive vacuum heat treatment process is a key aspect of this study, enabling efficient mass production of polymer solid electrolytes.”

More information:

Hyunwoo Kim et al, High-performance solid-state Li-ion batteries enabled by homogeneous, large-area ferroelectric PVDF-TrFE solid polymer electrolytes via horizontal centrifugal casting method, Energy Storage Materials (2024). DOI: 10.1016/j.ensm.2024.103260

National Institute of Standards and Technology

Read the full article here