As green hydrogen gains attention as a future clean energy carrier, the question of which renewable energy to utilize as an energy source becomes increasingly important. Among them, solar energy has the advantage of being available everywhere on Earth, with low dependence on natural topography. However, fluctuations in solar output and generation due to factors such as season and weather lead to repetitive increases and decreases in power, posing a challenge of damaging components of production devices. Therefore, precise evaluation of the durability of devices under power fluctuations is crucial for determining the optimal timing for component replacement and developing new materials.

Dr. Bora Seo’s research team from the Hydrogen and Fuel Cell Research Center at the Korea Institute of Science and Technology (KIST), led by Director Yoon Seok-jin, has developed a durability evaluation technique for green hydrogen production devices with step durations as short as one second, utilizing actual solar irradiance data. This represents the application of the shortest step duration among developed techniques, enabling the most accurate simulation of fluctuations in actual solar energy output. The work is published in the journal Energy & Environmental Science.

To increase the applicability of solar energy to green hydrogen production devices, a reliable durability evaluation technique is required. However, existing durability evaluation methods have not accurately reflected solar output variability, relying solely on simple methods such as periodic cycling or constant maintenance of current and voltage. Additionally, there have been no standardized evaluation criteria for assessing the durability of core materials for water electrolysis under power fluctuation conditions.

-

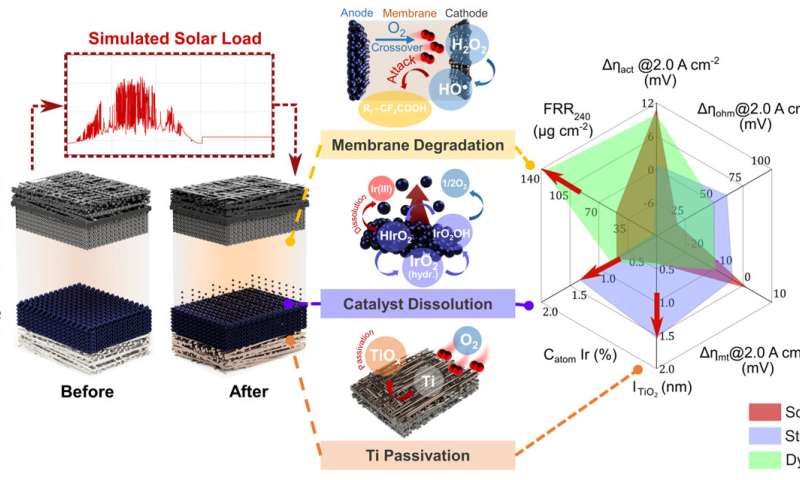

Degradation analysis of key materials for water electrolysis before and after solar-based durability evaluation. Credit: Korea Institute of Science and Technology

-

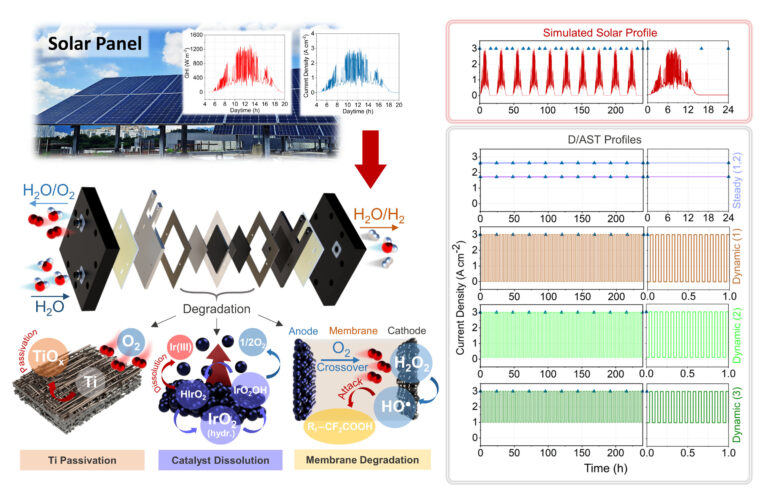

Durability evaluation experiment reflecting solar output variability for green hydrogen production devices. Credit: Korea Institute of Science and Technology

The research team has developed a simulation method that converts irradiance values into current densities using actual solar irradiance data obtained from solar panels, and using water electrolysis stack data. This has dramatically shortened the step duration from 10 seconds to 1 second, allowing fluctuations in solar output to be accurately reflected.

Moreover, based on the newly developed durability evaluation technique, the team has proposed key indicators for the material development of green hydrogen production devices.

Standardized analysis methods for assessing performance degradation of materials such as catalysts and electrolyte membranes, as well as indicators of performance degradation such as catalyst leaching amount, fluoride release rate, and thickness of passivation layer have been proposed. These guidelines can be utilized for the development of materials and components to improve the durability and performance of green hydrogen production devices.

The developed durability evaluation technique can diagnose the precise condition and predict the remaining lifespan of solar-based green hydrogen production devices, facilitating efficient equipment investment and enhancing competitiveness in materials and components.

This technology is expected to be applicable to assessing the performance of green hydrogen production devices based on other renewable energies such as offshore wind and tidal power.

Dr. Seo said, “This research achievement marks the first attempt to evaluate the durability of green hydrogen production devices by reflecting solar output variability most closely to reality.”

“This can contribute to efficient equipment investment and enhancement of competitiveness in materials and components for green hydrogen production systems.”

More information:

Anastasiia Voronova et al, Systematic degradation analysis in renewable energy-powered proton exchange membrane water electrolysis, Energy & Environmental Science (2023). DOI: 10.1039/D3EE01959D

National Research Council of Science and Technology

Read the full article here